4D model milling

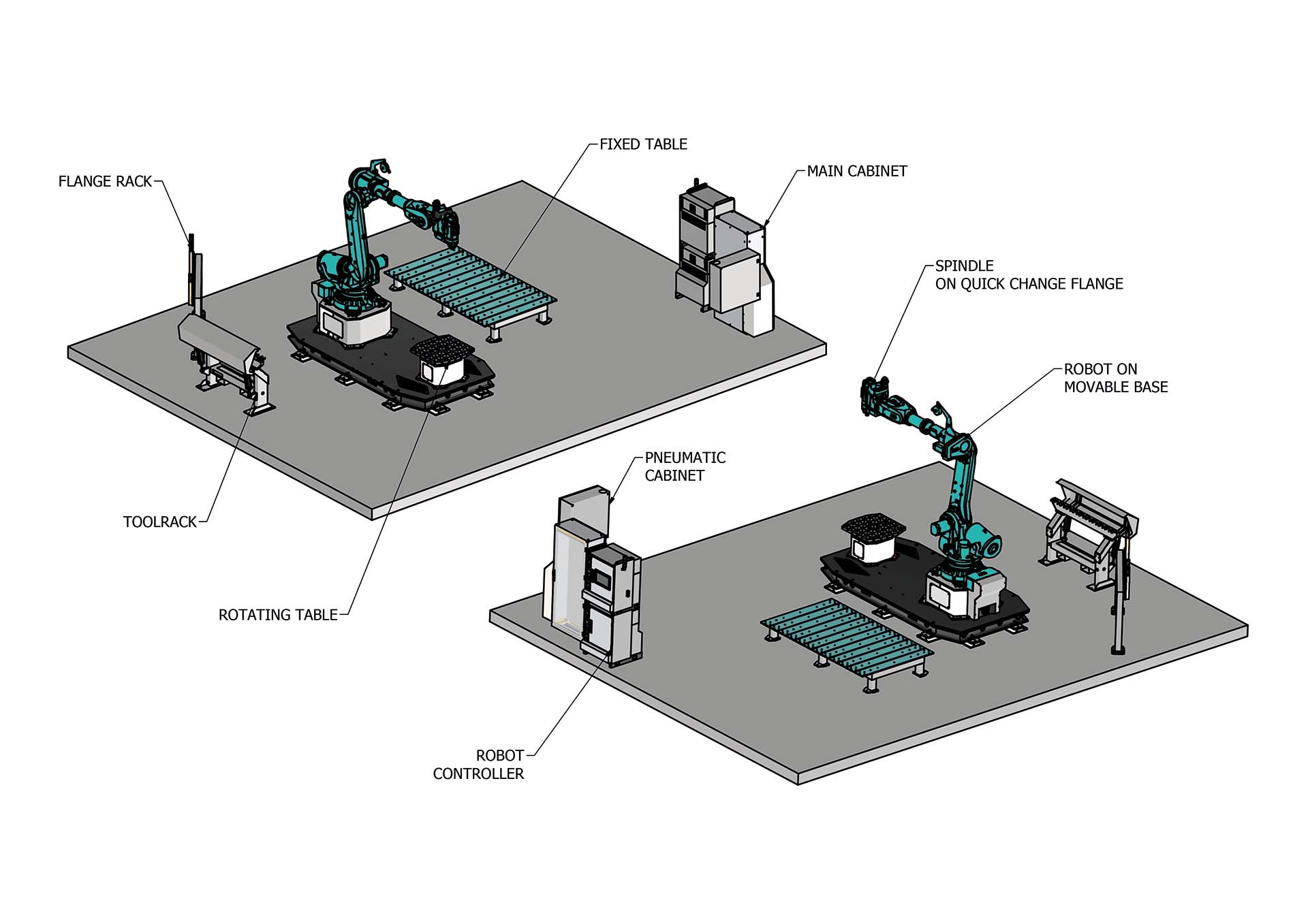

ESA 4D model mill is the 7- (or 8- ) axis robotics solution for three-dimensional milling (3D) of wood, polystyrene (EPS), resin and other materials. The system layout is designed to optimise the spaces available and maximise the machine working area.

The robot and electrospindle are chosen from a vast range based on the type of material and size of the workpieces to be machined. The solution includes the rotary table for moving the workpiece, the tool magazine (where present) for the automatic tool changeover and many other accessories for automating the work cycle.

The central role of the solution is covered by the software and process management components for which ESA has twenty years of experience. On the one hand, the programming of the system via any CAD/CAM system enhanced by the virtual simulation machining tool via our proprietary ROBOmove software and on the other, the ease-of-use and complete range of functions of the ESA CNC 4.0 man/machine/process interface for managing the entire system/process by the operator.

- Workpiece on the table or robot

- Polystyrene (EPS), wood, resin

- Automatic tool change

- Off-line CAD/CAM programming and virtual simulation