ESA FOUNDRY

ESA FOUNDRY consists of our CAD/CAM suite which includes macros and strategies dedicated to die-cast workpieces, and the adaptive algorithm for compensation for deformations.

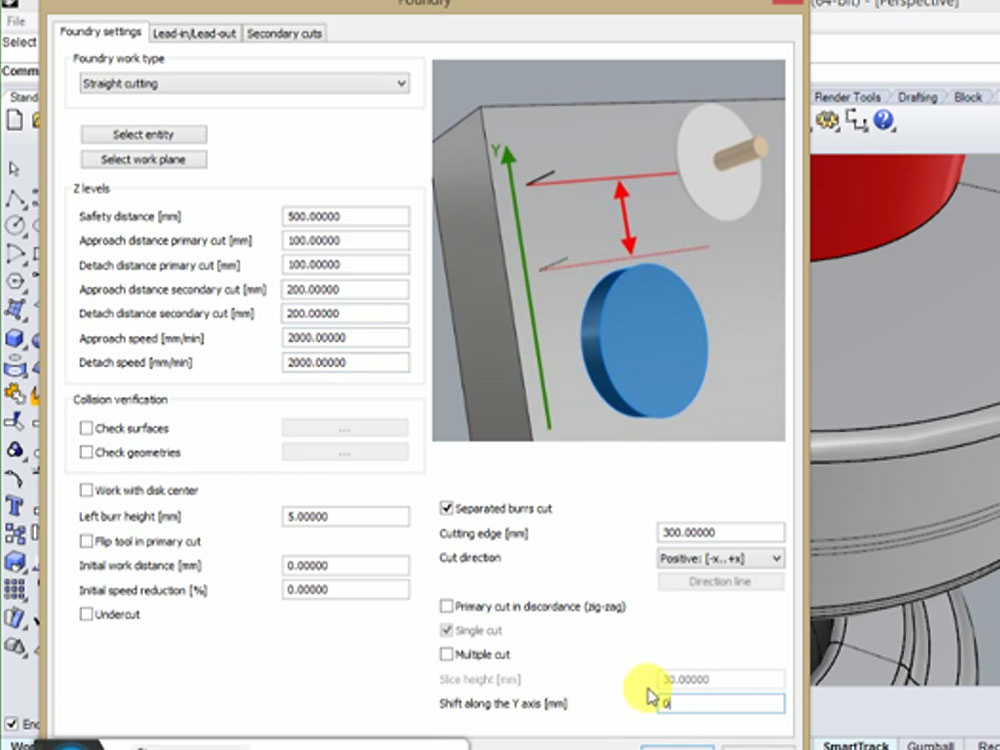

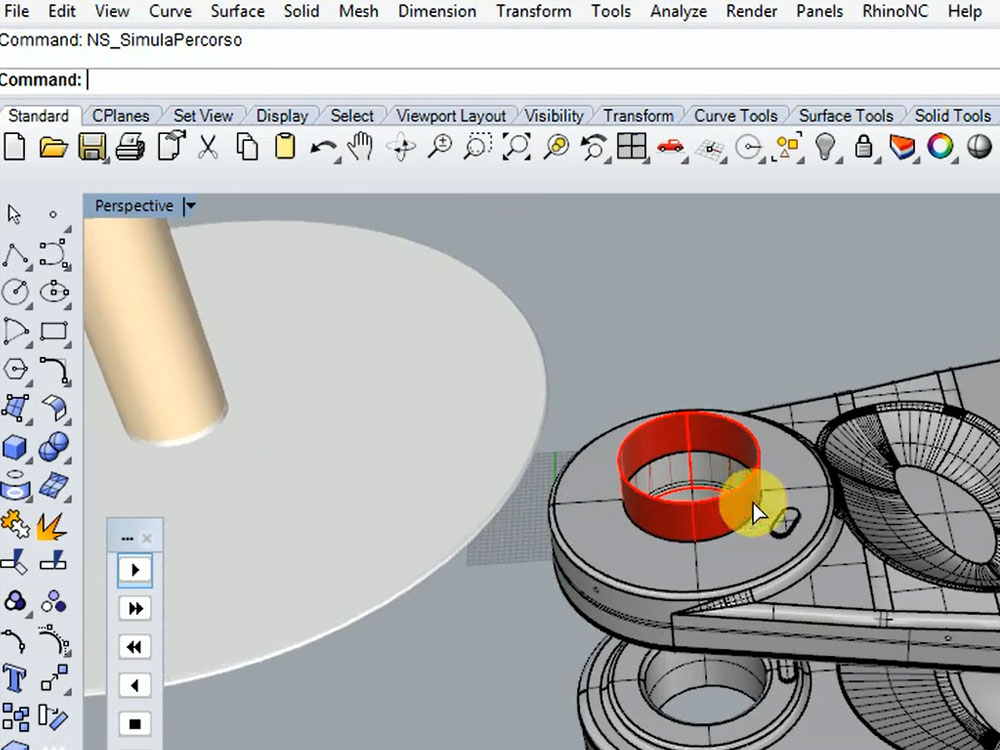

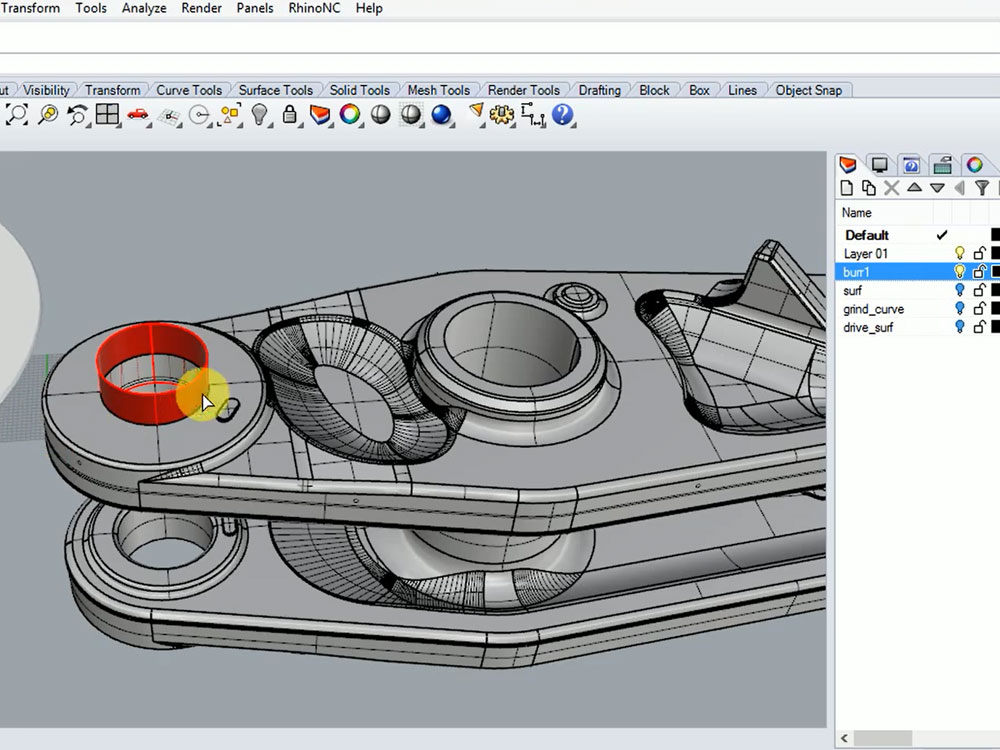

ESA FOUNDRY – CAD/CAM

A single CAD/CAM solution for generating tool paths for the machining of castings.

DEDICATED STRATEGIES

ESA FOUNDRY offers macros and strategies designed specifically for the foundry:

- Automatic generation of the tool path for pre-cutting of large burrs

- Vast selection of cutting strategies

- Automatic generation of the vertical cutting path of sprue pins

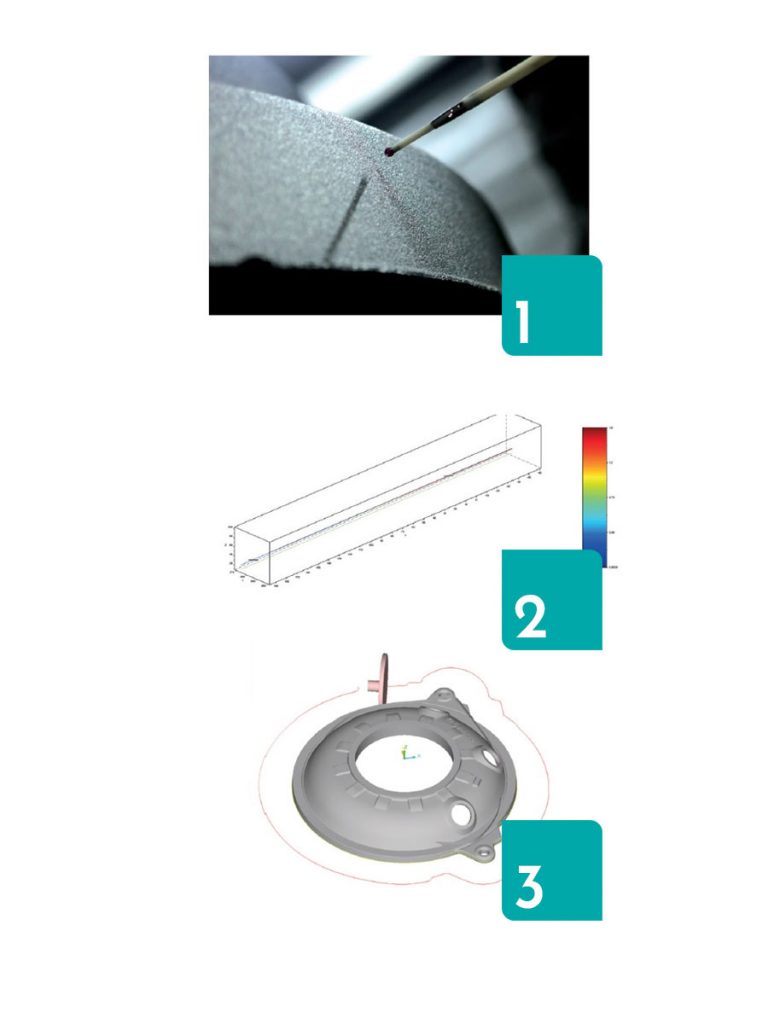

ESA FOUNDRY – ADAPTIVE ALGORITHM

Every casting is different due to the deformations generated during the production process. Our adaptive algorithm responds to the deformity between the actual workpiece and the relevant 3D model.

The use of the adaptive algorithm is based on the measurement of the workpiece. This operation also allows the position of the workpiece to be determined and, therefore, to define the home position. The accuracy in defining the position allows less precise and, therefore, more economic fastening systems to be used, thus resulting in cost savings.

Using a measuring system gives the robot CMM center functions and allows the system to carry out preliminary size checks on the workpieces to define their tolerances and discard them beforehand, if necessary, thus cutting down on machining time

The detection of deformations and the consequent recalculation of the tool path is performed in three steps:

- The robot uses the laser or sensor to measure various points on the workpiece

- The algorithm automatically changes the tool path to adapt to the real shape of the workpiece

- Generation of the new tool path

Software customizations

It is possible to customize ESA FOUNDRY based on specific customer requests and needs. Want more information about software customization?